Parmigiano-Reggiano D.O.C.- what can I say? One of the best hard cheeses on the planet. Not the imitations sometimes labeled Parmesan or Italian Hard Cheese found in many grocery stores throughout the States and certainly not the appalling, grated, shelf-stable, tasteless stuff packed in tubular cardboard packages. I’m talking about the amazing cheese made in Italy with the D.O.C. (Denominazione di Origine Controllata) designation.

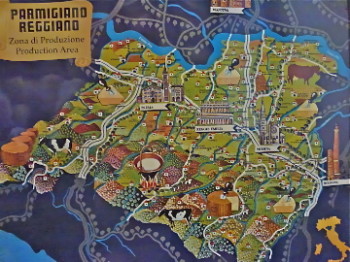

D.O.C. laws assure consumers that any product awarded that coveted designation is made in, and sources ingredients from, a specified region and is produced in accordance with specific, defined recipes and methods. Parmigiano Reggiano D.O.C. may

only be produced within the provinces of Parma, Reggio-Emilia, Modena, and part of Bologna (all in the Emilia-Romagna region) and Mantua (in the Lombardia region).

While in Parma, Italy we signed up for a private, full-day tour of food and wine producers in the region through a fantastic company called Food Valley on the recommendation of our daughter who took one of their group tours. I have no affiliation with this company and received no discounts, gifts or benefits so I can unequivocally highly, highly recommend them. Our remarkable, extremely knowledgable tour guide was given full access to the Monica family Parmigiano-Reggiano production facility. The company, with only 7 employees, was founded in 1933 and produces a whopping 9000 wheels per year.

Parmigiano-Reggiano is made from a mixture of whole and skimmed regional cow milk. The cows, under D.O.C. regulation, must be milked 4 hours or less before delivery and are fed a diet of largely fresh clover and alfalfa with some dry barley, oats and sorghum also allowed (absolutely no rice or maize is permitted as feed).

Fresh milk that arrives at the facility in the evening is held in large, shallow tubs to allow the cream to rise to the top.

The cream is drained off.

Bright and early in the morning, a new batch of milk is delivered. This fresh morning whole milk and the skimmed evening milk is pumped into huge, copper-lined, conical vats along with whey (to prevent, we were told, undesirable bacterial growth). The 1100 liter (290 gallon) mixture is heated to 34º C (93ºF ) and rennet is added.

After about 10 minutes, the curds, which have separated from the liquid whey, are manually broken up to corn kernel-size pieces using huge whisks.

The mixture rests at this temperature for 4 to 7 minutes then is raised to 55 °C (131 °F) and left undisturbed for about an hour. The broken-up curds compact and sink to the bottom. To extract the mass, the cheese makers tie large linen (or muslin) squares to wooden rods and sink the fabric into the vat.

Then, using huge wooden paddles, they carefully begin coaxing the mass onto the fabric.

The cheese makers go elbow deep into the whey using hands and short wooden paddles to get the entire 100 kilo (220 pound) mass onto the fabric.

Once the mass is on the fabric, they flip it.

(Note how it goes from pocked to somewhat smooth.)

Then they begin pulling it out of the liquid.

The cloths are tied to wooden rods laid across each vat.

Each large mass is cut in half.

The two halves are placed in separate pieces of fabric. One is left to hang while the other is lifted out and dipped into large buckets of water to rinse away the whey.

In the meantime, the whey is drained away from the vats and used to make ricotta cheese. The whey is also fed to the pigs used for Prosciutto di Parma (next producer stop on our tour). Each vat of milk yields 2 wheels of Parmigiano-Reggiano and about 60 to 64 800 gram (1.75 pound) baskets of ricotta. It takes approximately 550 liters (145 gallons) of milk to yield one 50 kilo (110 pound) wheel of cheese.

The heavy cheese-filled slings are carried to a table set up with adjustable willow wood molds. The ropes can be tightened or loosened to accommodate the varying sizes. Being hand-cut, each mass varies slightly in weight.

The cloth-covered fresh cheese is nudged and wiggled into the wooden forms.

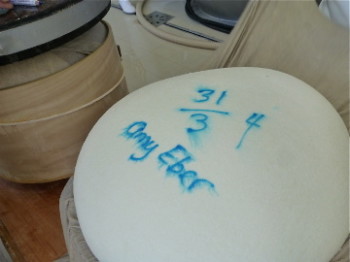

Each fresh cheese is marked with a food-safe, delible marker (which washes away during brining) stating which vat it came from. After marking, oak rounds weighing about 10 pounds are placed on top to further extract liquid.

The owner’s son let me mark and sign one of them.

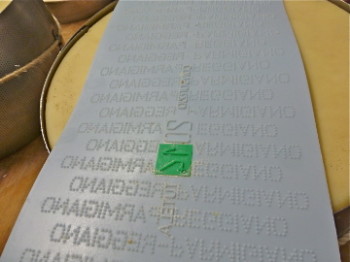

The next step is transferring the fresh cheese from the wood mold to a metal mold punctured throughout. The cheese rests in these for 2 to 3 days. As the moisture drains through the holes, the cheese shrinks a bit and pulls away from the sides.

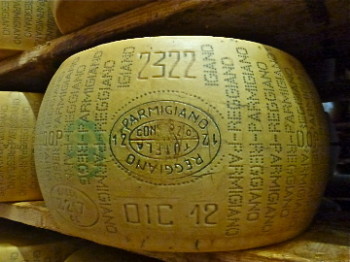

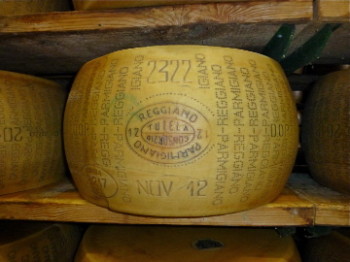

It is in this room that each wheel is imprinted with sheets that mark the sides with the Parmigiano-Reggiano name, the plant’s number, the month and the year of production.

The final imprint, after aging, looks like this:

The wheels are next transferred to the salting room. Salt is added to perforated baskets sunk into massive tubs of water. The cheeses bob away in the brine bath for 19 to 25 days, being turned daily.

Now the aging begins. Cheese wheels are stacked ceiling high on wooden shelves.

Over the next 1 to 2 1/2 years, each must be periodically turned and dusted. This producer uses a machine to do both.

Note the “dust” that comes off of the cheese as it ages.

Every single one of the 9000 wheels produced annually is tested. One-by-one, each is balanced on its side on the socca stool pictured below. After a visual inspection, the wheel is tapped to hear if it is solid, sniffed to detect if anything is “off” and injected on its side with a needle so a taste test can be done before it is released for sale.

As the Parmigiano-Reggiano ages, it becomes drier and sharper tasting. I asked how how much the originally 50 kilo wheels weighed (approximately) after they aged and was told 12 month old wheels weigh 38 kilo, 24 month old wheels weigh 35 kilo and 36 month old wheels have shrunk to about 32 kilo. We purchased almost 20 pounds of different aged Parmigiano-Reggiano and are happily sharing and slowly working our way through our vacuum-sealed haul.

Speak Your Mind